Lift Technologies, Inc.

Complete front-end solutions for mobile material handling equipment.

Lift Technologies supplies masts, carriages, integral sideshifters, fork positioners, reach carriages and related components for a wide variety of mobile material handling equipment. These products are used on industrial trucks, automatically guided vehicles (AGVs), telehandlers, truck mounted and rough terrain forklifts and a broad range of other material handling applications.

Masts

Carriages

|

Options

Parts

Fabrications

|

Company Profile

Lift Technologies, Inc. is a global leader in the design and manufacture of masts, carriages, integral sideshifters and fork positioners for the mobile material handling market. Our customer base is broad and includes those with industrial truck, rough terrain, construction and agricultural equipment applications. Masts are available in two, three, four and five stage configurations, in capacities globally from 1.5 to 48.0 metric tonnes and are used in a wide variety of applications.

Material handling products are used on electric and internal combustion counterbalanced lift trucks, narrow aisle lift trucks, automatically guided vehicles, side loaders as well as container handling applications. Rough terrain and truck mounted forklift masts, reach carriages and telehandler carriages are also available.

The company has manufacturing plant locations in Westminster, South Carolina USA and Piacenza, Italy. These are specialized production facilities that offer both high volume line flow production as well as dedicated flexible cell work centers for lower volume, custom requirements, all on a just in time basis. Completely integrated front end solutions are available in a wide variety of capacities and configurations.

For more information about our company, please download this brochure.

Production

Lift Technologies invests in the latest tooling and robotic technology which drives consistent high quality and an efficient production process.

Lift Technologies’ employees are dedicated and experienced, providing added value to the manufacturing and support processes.

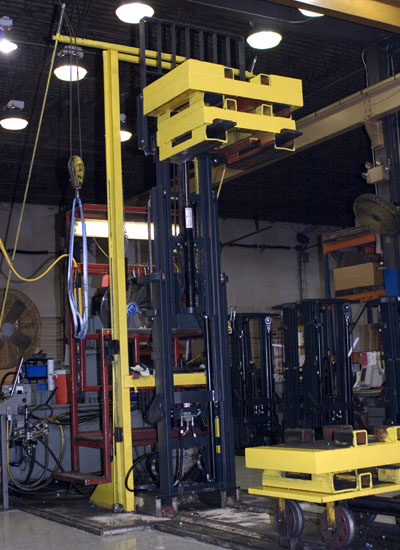

10,000lb Quad Mast

Engineering Expertise – Customer Focus

Lift Technologies’ engineering teams are customer focused. Their mandate is to work closely with customers to provide complete "front end solutions" to solve the performance and application challenges our customers face every day.

Experience, knowledge and a strong communication path with our customers allows a clear understanding of applications which results in optimal mast designs to suit the specific truck and end user need.

Quality

Lift Technologies promotes a quality culture with all areas of the company actively involved in the quality process.

Continuous improvement activities are ongoing and are tracked internally as well as being monitored together with our customers through shared quality initiatives.

A process based quality system is utilized throughout the manufacturing process ensuring ongoing adherence to the standards in place.

Click to view our ISO 9001:2015 Certification

Product Development Test Lab

The Product Development Test Lab at Lift Technologies was established to develop and improve our products, and is also available as a resource to our customers.

Our goal is to provide quick set-up and turn-around of realistic tests on fork lift masts and attachments. Automated test stands allow unattended cycle testing of high-endurance articles.

A flexible attachment system allows a wide variety of equipment to be mounted and tested.

Material Handling Customers

Lift Technologies supplies a wide variety of products to industrial truck customers including masts used on counterbalanced, narrow aisle, reach and side loader trucks. The company also supplies a variety of masts to the AGV industry as well as full spectrum of masts and telehandler carriages used in rough terrain applications. Our end customers include those involved in warehousing and logistics, food and beverage, cold storage and freezer, construction, steel processing, pulp and paper as well as container handling.